Kent Lewis

Kent LewisScrews can hold work pieces together in areas where clamps can’t reach, and fender washers spread the pressure over a wide area, minimizing the damage to the wood and helping prevent splits in lumber.

In our shop we have a lot of tools that have come to good use when working on wooden boats. One of the least conspicuous is a pile of small zinc-plated fender washers.

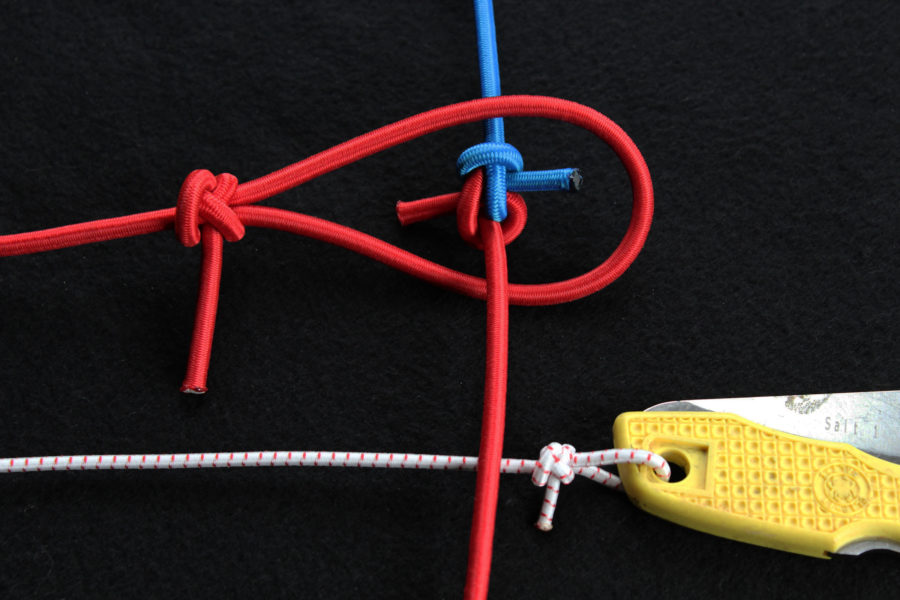

With oversize diameters and small holes, fender washers were developed for working on automobile fenders where the sheet metal would be distorted when pressed by smaller washers. I can’t remember where we came across the idea to use them in working on wooden boats, but I am glad that we did. We often encounter tasks that are beyond the reach of clamps, and a fender washer and a screw can pull parts together, like bending a plank into position on a frame, stem, or transom.

Peter Sibley

Peter SibleyBar clamps might reach across the side decks to secure the sheer guard for gluing, but screws and fender washers are a more economical approach, less expensive even than stainless or bronze screws that would be left in place after the glue cures.

We’ve tried to close gaps between pieces using the wood screws that will be the permanent fastenings, but found that method fraught with problems. The heads of wood screws can bury themselves, damaging the workpiece and then becoming difficult to remove without lifting and splintering the top fibers of wood. And the conical underside of a flat-head screw can act as wedge and split a plank end. The finer threads of silicon-bronze or marine stainless-steel screws may not bite as well into softer wood, and while those screws can be used to hold parts together, they’re not well suited to closing gaps. A screwdriver can also cam out of the slot in a softer bronze screw head, requiring replacement of the damaged screw. To avoid these problems, we use fender washers with drywall or deck screws as temporary fastenings while we drill for and install the permanent fastenings.

Peter Sibley

Peter SibleyScrews and fender washers are especially useful holding the hood ends of plywood planks to the stem while epoxy cures.

Fender washers are especially useful when working with softer hardwoods. We once needed to pull a cypress plank tight to a frame during a repair and first tried using a single silicon-bronze wood screw, but the screw buried itself under the surface, did not have enough bite to pull the plank, and stripped out of the frame. We then tried using several bronze wood screws to distribute the load but ended up shearing some of them, and nothing is more fun than dealing with half a screw in a frame while the plank is not pulled tight. When we switched to a fender washer and a deck screw we fared much better. A deck screw’s star-drive head has an exceptionally secure hold on the driver bit, and the longer, coarser threads of the deck screw bit right into the frames and pulled the plank tight. Once the cypress plank was properly positioned and the permanent fastenings were installed, we removed the deck screw and used that hole for another permanent fastening. In some cases, we’d fill the hole with thickened epoxy or a wooden plug.

Peter Sibley

Peter SibleyScrews and washers kept molten lead from seeping between layers of plywood for a centerboard that will later be epoxied together and sheathed with fiberglass.

We also use fender washers when working with plywood panels. The washers prevent damaging the layers of ply while the panel is being shaped to the molds and fastened. Without the washer, the screw head might crush the multiple thin layers of plywood, either leaving a lot of damage to finish, or even compromising the integrity of the panel. A rough-cut panel can be left on a mold for a few days to help preset a bend, making final installation easier. If the plywood is reluctant to make a bend you can help it along by covering it with towels, pouring boiling water over them, then covering it all with plastic sheeting to hold the heat. Use zinc-plated or stainless-steel washers—plain steel will stain the wood black.

A fender washer and a screw don’t cost much, under 50 cents for the pair, and a handful of them can get you through jobs where clamps can’t be used or you don’t have enough of them.![]()

Kent and Audrey Lewis used quite a few fender washers during the restoration of their 1880s Mississippi River Skiff BARBASHELA and their 1950s Alcort Sailfish ZSA ZSA. More information on their continuing adventures can be found on their blog Small Boat Restoration. www.smallboatrestoration.blogspot.com

You can share your tips and tricks of the trade with other Small Boats Monthly readers by sending us an email.

Good article. I much prefer deck screws to drywall screws because they are stronger and not so likely to break off in the wood when securing epoxy-bonded joints. I also find that a hammer-driven impact driver is handy to break the bond of the epoxy to loosen the screws before trying to back them out with a screw driver or power driver.

I’ve used washers in similar ways, it is a very helpful article!

Best,

Roy

I use fender washers all the time. Especially when doing a wood-strip deck. The screw is inserted between the two strips and a fender washer holds them in place. On the outside edge of the strip I use a piece of wood the same thickness as the wood strip to support the unsupported side of the fender washer.

I wrap clear packing tape over the washers to keep them from sticking to the project if epoxy seeps up through the screw hole.

When building the wooden Drascombes, we used square nuts and hex-head bolts and washers, or screws and washers to clamp the plank lands together when gluing them in place. When the glue had cured, the fastenings were removed, the holes drilled out to clean wood, then hardwood dowels glued in the holes. Very effective system to get a tight joint in places where clamps are difficult to use, it also allows the work to continue without the obstruction of clamps, although we used a lot of them as well. For clamping together with the nuts and bolts, we used spanners, for removing them, we used a speed brace and socket, the glue usually held the square nuts in place sufficiently inside the hull, a sharp light tap with a hammer is enough to release the nuts afterward. This system is also ideal for repairing damaged sections that required a flush finish, or plank scarf joint; for that we used a removable butt strap on both inner and outer sides of the scarfs joint to spread the load past the edges of the scarf, this way you can get a nice flush finish, even where there’s a curve in the plank.

At the East End Classic Boat Society’s Community Boat shop we use fender washers to force gains down into their proper positions on transoms and stems. We use them when the plank is just out of the steam box to hold the twist at the bow and the curve of the transom at the stern and when installing the plank with adhesive sealant in the laps.

Note that the washer holding the forward end of the plank has been bent to fit into the angle between plank and stem, preventing the edges of the washer from damaging the wood.