photographs by the author

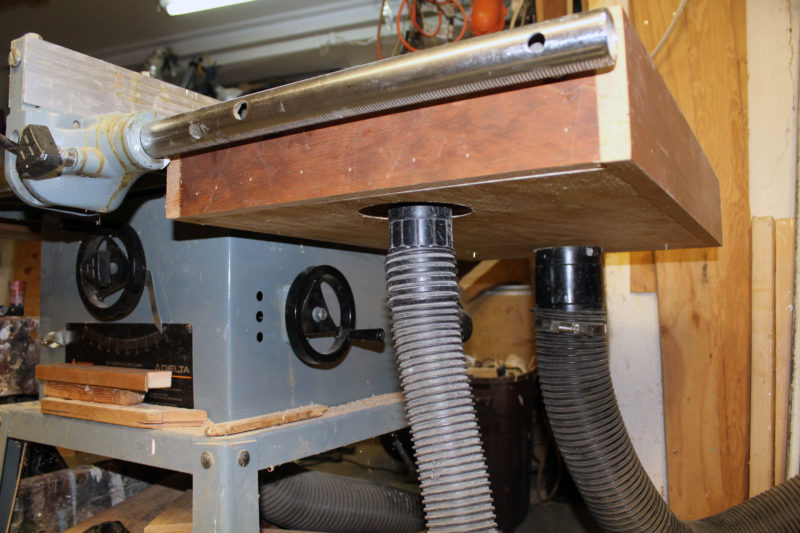

photographs by the authorA simple downdraft table can put the space between the rip-fence rails to good use.

Building and maintaining a wooden boat involves a lot of sanding and a lot of dust. I have an exhaust fan for the shop, a dust collector connected to my tablesaw and jointer, and shop-vacuum connections for the belt sander, disc sander, bandsaw, and random-orbit sander. My latest addition to my arsenal of dust-collection devices is a shop-built downdraft table. It comes in handy for capturing the dust from sanding small pieces by hand or with a random-orbit sander. There’s nothing special about the box. I used 3/4″ fir from some old shelving and 3/8″ plywood for the top and bottom. Most of the downdraft tables I found on the web had interior panels sloped to draw the coarse particles toward the hose fitting, but with my shallow box, I didn’t think they would be very effective. The top is removable, so it is easy enough to get to the interior with the shop vacuum whenever it’s time to clean up the interior.

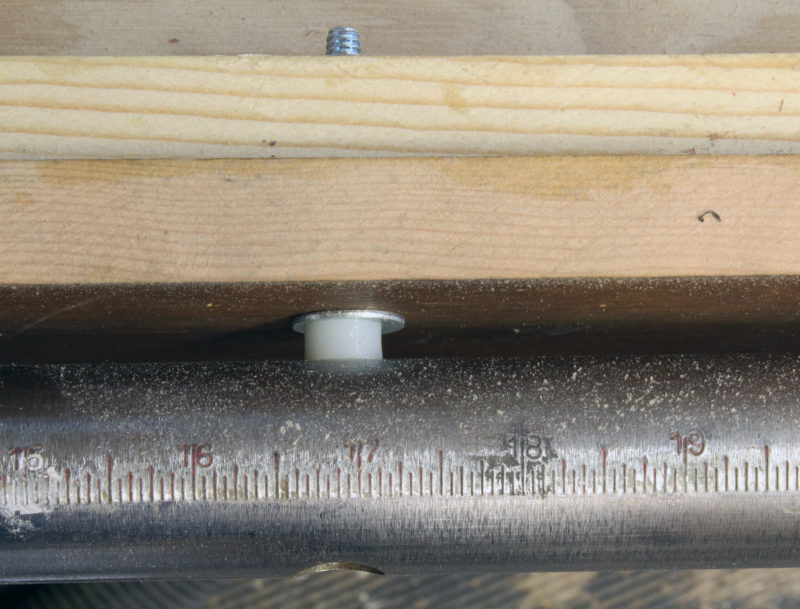

The downdraft table must provide clearance for the rip fence. A washer and a 1/4″ nylon-sleeve spacer work for this tablesaw.

Cleats set inside the perimeter of the box provide ledges for the plywood after they’ve had their holes drilled. The top has a grid of 7/8″ holes drilled on 2″ centers; the bottom has one large hole to fit the dust-collector hose fitting, and a second smaller hole to fit the shop-vacuum hose. The bottom is glued and nailed in place. The dust collector normally does the work while the downdraft table is in the shop, and I’d take the table and the shop vacuum for jobs elsewhere. A foam plug blocks the unused hole.

I had to drill an additional hole in each of the rip-fence rails to support the downdraft table. Your tablesaw may require different modifications.

Additional pieces of plywood reinforce the perimeters of the holes for the shop-vacuum and dust collector hoses. A foam plug normally keeps the idle shop-vacuum hole closed.

The dust collector is hooked up to the back of the downdraft table, the shop vacuum at the front. The shop vacuum is used if the downdraft table is removed for work outside of the shop table; its hole is plugged when the dust collector is in use. The box is shallow enough to maintain clearance for the tablesaw’s tilt control.

Stops come in handy for keeping the workpiece from drifting while it’s being sanded. These are short sections of 1″ dowel with one end trimmed to fit the 7/8″ holes in the table top. A piece of paper draped over the unused area of the table increases the airflow around the workpiece.

A box fan with a 20″ x 20″ furnace filter will pull stray particles in. The fan’s own suction is all that’s needed to hold the filter in place. Letting the fan run whenever there is dusty work being done in the shop will recirculate air and capture dust.

The downdraft table doesn’t interfere with the operation of the tablesaw. The fence slides over it and I have enough room under it to adjust the tilt without barking my knuckles. The extra surface area supports pieces being sawn on the right side of the blade and offers a place to set push sticks, pencils, and measuring tools. The downdraft table helps assure that what happens in the shop stays in the shop.![]()

Christopher Cunningham is the editor of Small Boats Monthly

You can share your tricks of the trade with other Small Boats Monthly readers by sending us an email.

The lead-in was the down draft table, but the simplicity of the furnace filter on the box fan is what I’ll take away from this. Thanks.