Photographs by Jon Wiegand

Photographs by Jon WiegandJon Wiegand once summed up what drew him to building boats: “Wooden boats are just classy.” While that may not always be true, his canoe proved that a good design in the hands of a skillful builder is sure to be a class act.

Jon Wiegand grew up in Iowa, not far from the Iowa Great Lakes, a chain of natural lakes in the northwest corner of the state. As “great lakes” go, they are rather small—the greatest of them is just shy of 9 square miles, so you could never be out of sight of land—but they had a big impact on Jon. His father used to take him fishing on the lakes closest to his home, and those outings fostered his fascination and love for wooden boats.

Photographs by Jon Wiegand

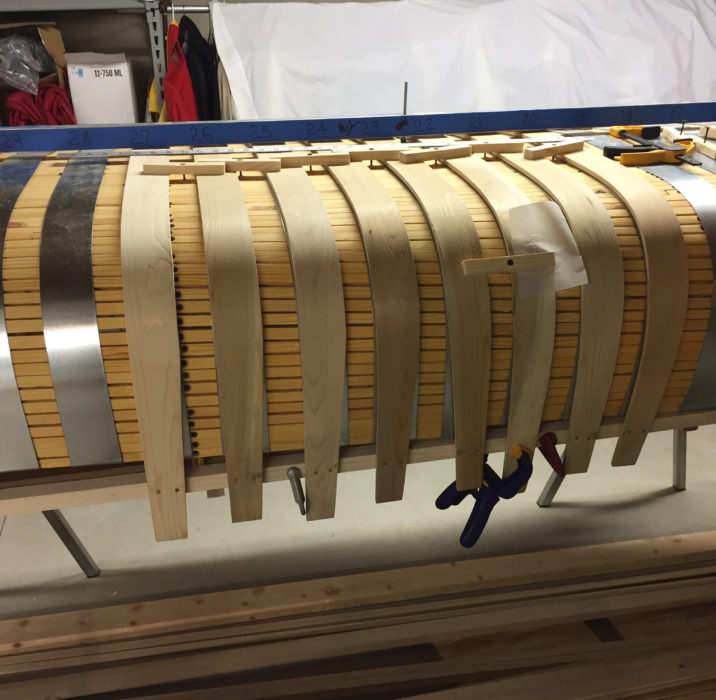

Photographs by Jon WiegandBands of steel are placed where each rib will go and will turn the points of the canoe tacks that fasten the planking. What appears to be a keel will hold the ribs tight against the hull while they’re being bent.

Freshly steamed ribs are slipped under the bar above the centerline and wrapped around the steel bands. The cleats spanning pairs of ribs are screwed to the form to keep the ribs from arching upward.

When Jon had a family of his own, he did what those inexorably drawn to wooden boats often do: built boats for his children. The first was a 17′ strip-built canoe, a birthday present for his daughter. To be fair, he had to do something equally grand for his son, so he went right to work on a second strip-built canoe. It’s said that when you’re taking up something new, you should try it once to see what it’s like, and a second time to see if you like it. Jon decided he enjoyed boatbuilding, so he kept at it. His wife was boatless, so he gathered up supplies for a third project, this one a strip-built kayak.

Much of the planking can be applied with very little trimming to achieve a tight edge-to-edge fit, and because the planks will be covered with canvas, there’s no need for lining-off planks for appearance’s sake.

A move to the outskirts of the city of Green Bay, Wisconsin, interrupted Jon’s serial boatbuilding, but didn’t bring it to an end. The new home had ample room for a shop and its own sandy beach on Green Bay. The view from the living room offered more of a “great lake” feeling with the far shore of the bay just a slim line along the horizon. It was inevitable that Jon would soon feel the lure of another project to take advantage of the water at his doorstep.

After being lifted from the form, which is now leaning against the wall, the hull has temporary cross spalls to hold it in its proper shape. The last of the planking can now be applied.

He upped the ante considerably by deciding to build a wood-and-canvas canoe in the traditional manner. If you like to build things, it’s a good way to go: you get to double your fun (not to mention the time and expense) by building the form required and the canoe. Jon got his plans from Stewart River Boatworks in Knife River, Minnesota. The Fishdance model he chose is listed as a 15′ 6″ Sportboat. Named after a lake in the Boundary Waters Canoe Area of Minnesota, it’s a square-stern canoe with a beam of 43″, so it’s meant for rowing and motoring rather than paddling. With the bigger boat Jon would be better able to manage the wider waters of Green Bay in his backyard.

With the hull pulled off the form, you can see that all of the points of the canoe tacks are bent and well buried in the ribs.

The build started with the form that the canoe would be built around. It was very much like a strip-built boat shaped around a dozen plywood forms, only with thicker strips. The strips don’t need to be tightly fit to one another, but they do have to be fair from stem to transom. Wherever there was to be a steam-bent rib in the canoe, there was a metal strap on the form, which would turn the points of the clench nails that would eventually be driven through the canoe’s planks and its 44 ribs and 37 narrower half ribs.

The filler that’s used to smooth the canvas skin takes weeks to dry. Before it was applied, the canvas at the stern was trimmed, tucked under, and sealed with a bit of caulking before being tacked to the transom.

The canoe began to take shape when the ribs were steamed and bent over the form. Jon had never done steam-bending before, and was a bit daunted by the task. He did a lot of research online and built an insulated wooden steambox, bought a propane burner designed for deep-frying a turkey, and a turned a cleaned propane cylinder into a boiler. It didn’t take long for him to discover that steam-bending isn’t a great mystery, but rather, as he put it, “one of the most satisfying experiences” he had during the build.

With the filler finally dry, the canoe takes its final coatings of paint.

The planking followed. Working the thin stock was easy, and the gaps between the planks needed only to be snug, not airtight. Canoe tacks, over 1,500 of them, were driven through the planking and into the ribs. When the fine points of the brass tacks emerged and hit the steel bands on the form, they bent and turned back into the rib.

When the hull was finished, Jon stretched canvas over it, tacked it in place, and applied the filler, a traditional paint-like concoction that’s thickened with silica. It’s a messy job rubbing it into the canvas until the weave is filled and the skin has a smooth surface. Jon was forced to take a break from working on the canoe for the month it took the filler to dry.

A rare find: a 1953 outboard in mint condition.

A traditional square-stern canoe wouldn’t look right with a modern outboard, so Jon went on an extensive search for a vintage motor. He had the good fortune to locate a 1953, 3-hp Johnson Seahorse in mint condition. He and his wife bought it as a present to themselves on the occasion of their 50th wedding anniversary in August 2018.

The well-preserved 65-year-old outboard motor is a good match for Jon’s newly launched canoe.

Jon followed the advice of Spring River Boatworks and installed folding outrigger rowlocks. They each add 4″ to the span, allowing the use of longer oars for a more comfortable stroke.

The whole project took eight months. “It helps when you’re retired,” Jon notes. He launched the canoe on October 22, 2018, on Green Bay. It was a crisp fall day, the motor performed flawlessly, and the oars just came along for the ride. Jon didn’t have much time to enjoy the fruits of his labor, as Green Bay ices over in December. The canoe is in the garage, the outboard is in the basement, and Jon is mulling over his next project. He’s thinking lapstrake.![]()

Have you recently launched a boat? Please email us. We’d like to hear about it and share your story with other Small Boats Monthly readers.

Wow! Beautiful work Jon. Congratulations on a great accomplishment.

Glad to see a Midwest story! I learned to sail on West Okoboji* on a Butterfly.

*one of the Iowa Great Lakes. Ed.

I would be interested in the composition of the paint-like canvas filler.

The canvas fillers made up of linseed oil, silica powder, and Japan drier. The one-gallon can it comes in is hard to mix as the silica settles to the bottom. Pour off the liquid and remix it while adding the small portions of the liquid back in. Its a messy job, so wear gloves.