all photographs by Adrian Morgan

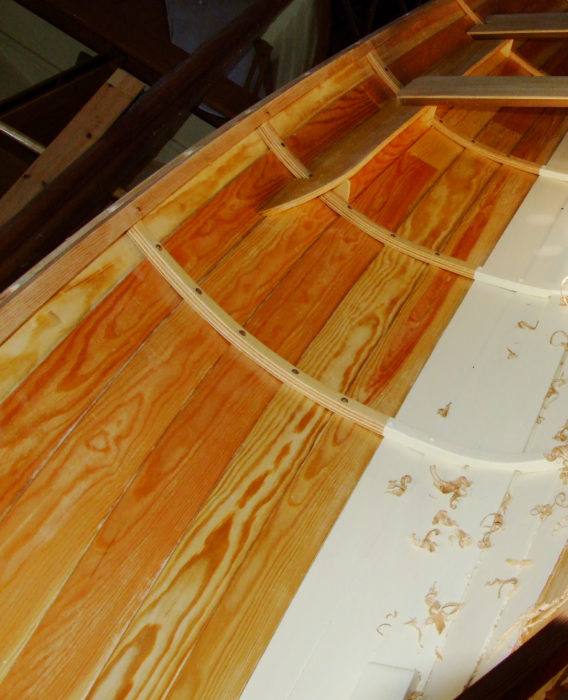

all photographs by Adrian MorganThe 6mm Vendia planking has four of its five veneers running lengthwise; it easily twisted to meet the stems.

Adrian Morgan builds traditional boats by the shores of Loch Broom, a long inlet on Scotland’s west coast. He does business as Viking Boats of Ullapool, and has devoted himself to preserving traditional forms and methods, so it was quite a departure for him to use a recently developed laminate for planking instead of locally harvested larch and oak to build a rowing skiff for his friend Jan.

The design chosen for the boat was Paul Gartside’s 16′ Bob, a double-ended beach cruiser. While the plans were drawn up for strip planking, glassed inside and out, for Adrian “there was only one method: lapstrake. That would entail radical departure from the beautifully drawn plans. The planking, framing, and stiffening would have to be worked out from scratch.”

The frames are laminated from off-cuts from the planks. Their rivets are the only fasteners set in the laps.

While the conversion would take Adrian back to familiar territory, his choice for planking material would venture into new ground. Vendia is a laminated boatbuilding material made in Finland. Unlike rotary-cut plywood, it is made from veneers cut, rather than peeled, from logs with either vertical grain of flat grain, just like sawn lumber. That limits the width of the laminations—they can’t be made as wide as plywood sheets created by peeling a continuous veneer from the log—but provides the look of lumber and veneers less prone to cracking. Vendia laminates have all, or nearly all, of the veneers running lengthwise so it works like lumber and even has the fragrance of the pine it’s cut from.

The Vendia planking looks like sawn lumber but can have flat grain on one side and vertical grain on the other.

With Vendia, Adrian could build the Bob as a glued-lapstrake boat and forgo fastenings at the plank edges. For an adhesive “rather than using epoxy, a glue I hate with a passion for its mess, mixing, and waste, I have been using Collano Semparoc on a number of glued-lapstrake boats. It sets hard, almost as hard as epoxy, cures in about the same time, can be sanded, and needs no mixing or fillers. And as it expands it has a limited but strong gap-filling effect.” Adrian used planking offcuts for making frames—he laminated three layers of the 6mm Vendia using the building molds as jigs.

The thwart set here in the amidships position for solo rowing can be moved aft for tandem rowing.

WENDY was outfitted as a rowboat, leaving the rudder and lug rig perhaps for a later time. (The boat was designed without a centerboard, reasoning that upwind progress would be better made under oars.) The bright-finished Vendia looked like traditional planking without the hundreds of lap fastenings. Adrian had no doubt the boat would row well. He said, “Some boats look sweet and fast before they hit the water, and the Bob certainly falls into that category—fine-lined and slippery.” Regarding her performance, he said “She did not disappoint, accelerating with minimal effort to cruising speed.” WENDY floated right on her lines with one or two rowers aboard and tracked well thanks to the long, nearly straight keel.

The 9′ 3″ oars were just the right length and the Australian Gaco oarlocks were virtually frictionless and allowed the trapezoid oar looms to be feathered.

Adrian’s experiment with modern materials was a success. “Vendia,” he said “brought together a new material with an old method. Light, strong, easily worked, and above all capable of taking a clear finish to look like solid timber, it was a material I looked forward to using in all my future boats.”

Soon after Adrian launched WENDY, Vendia abruptly announced that it had discontinued production of its Marine Plank due to insufficient demand. The ensuing outcry seems to have caused some rethinking of that decision, however, and the company is seeking a way to keep the product going. Interested readers should visit the company’s web site for the most up-to-date news. [Editor’s note, January 2021: Vendia’s web site is now offering the planking again.]

“Vendia,” Adrian said, “was the only reason I decided to keep building boats. If it’s plywood from now on, then I’m out of it.” But, a month later, the shock had worn off and he had started building an Auk dinghy—in traditional materials. (You can track his progress on his blog: thetroublewitholdboats.blogspot.com)![]()

Have you recently launched a boat? Please email us. We’d like to hear about it and share your story with other Small Boats Monthly readers.

Gorgeous boat and exceptional craftsmanship! I was one of the people who read the article about Vendia in the September/October 2015 issue of WoodenBoat and was really excited about using it, only to visit the Vendia website and discover that they were shutting down the operation. I hope they figure out how to hand off the business to someone else, because it’s an exciting-sounding product.