ZO Boats is a new company started by Bill Koffler and Scott O’Connell, partners in Aquidneck Custom Boatbuilding, a company specializing in high-tech composite construction. [Note: This review is now archival material. The company is no longer in business.—Ed.] Involved in modern yacht construction for many years, they came up with a decidedly simple idea for ZO Boats: to offer small-boat kits that allow the novice home builder to produce professional results. The boats were to be as simple to use as they were to build, with no sacrifice of performance or beauty. Dave Walworth, a naval architect, drew up the designs in collaboration with Bill and Scott and now ZO Boats offers three models: the goZO, an 8′ pram designed for the true beginner; and the rowZO and sailZO, both versions of a 15′6″ flat-bottomed skiff design. I was lucky to have a morning with Bill, rowing and sailing the sailZO in the waters around Bristol, Rhode Island.

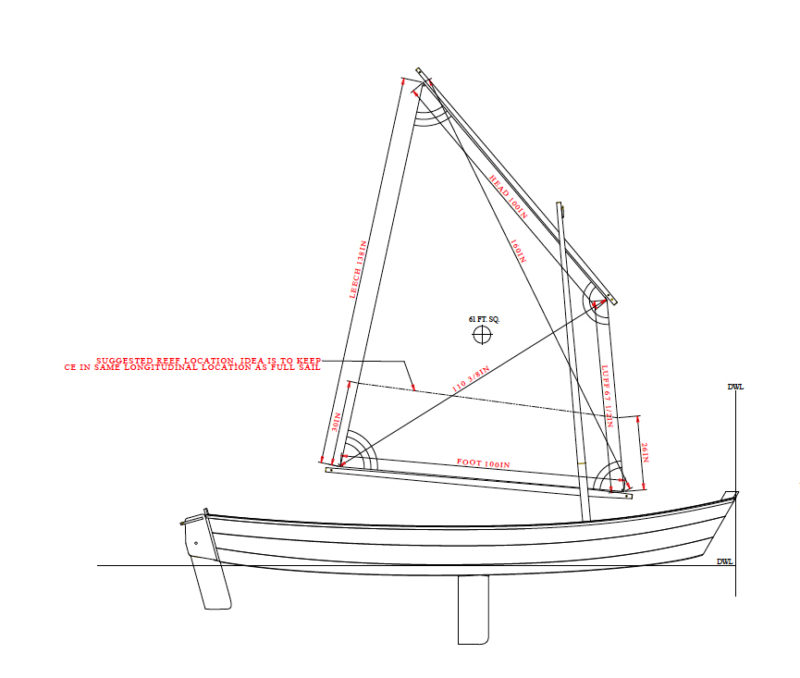

The sailZO is a 15′8″ double-chined skiff with a beam of 4′5″, designed to perform well under both oar and sail, carry three adults, and afford a couple or a small family the opportunity to explore coastlines and lakes, whether for an afternoon, or an overnight camp-cruise. The boat has three thwarts, each with a set of rowlocks, as well as a bow seat and sternsheets. With the centerboard and rudder retracted, the hull draws mere inches and under oars can poke into backwaters and glide over shoals. For sailing, the boat uses a simple free-standing lug rig stepped through the forward thwart. This was chosen for its ability to generate ample power while keeping the center of effort low, and to complement the traditional look of the boat. A high-aspect-ratio centerboard is enclosed in an unobtrusive trunk that spans between the second and third thwarts. The rudder is a kick-up type and steering it is accomplished by means of a continuous rope which passes through fairleads in the frames around the interior of the boat a few inches below the gunwale. The ends of the steering line pass through the transom and are made fast to the rudder’s yoke. This arrangement enables one to steer from anywhere in the boat.

courtesy of ZO Boats

courtesy of ZO BoatsThe kits include all of the precision cut okoume plywood parts for the boat—including foil-shaped rudder and centerboard blades—and for the strongback, with legs to bring it up to a convenient working height.

There are two kits available, basic and complete. The basic kit includes all the plywood parts needed to build the hull, including seats, centerboard trunk, and rudder. The supplied hardware includes screws, binding wire, pivots for the centerboard and rudder, as well as copper tubing and a flaring tool to make up the steering-line fairleads through the frames. A plywood building jig, as well as a scarfing clamp, are included. All plywood parts are CNC cut and ready to assemble. The long pieces require scarfing, but the joints are precut hook scarfs, and in conjunction with the scarf clamp, result in precision joints without much fuss. The planking is sprung over the frames, stem, and transom—all aligned on the jig—and secured with screws. Bill assured me that their precision-cut planks require no trimming or bevels, and that the planks lie nicely over the frames right out of the box. He did mention, however, that an occasional wire stitch does help with the alignment, but many fewer stitches are used than in typical stitch-and-glue construction. Once the planking is in place, the seams are joined with epoxy fillets inside and out, and the whole hull is coated in epoxy. The kit includes 6-oz fiberglass cloth to give the exterior abrasion resistance and stiffen the hull.

courtesy of ZO Boats

courtesy of ZO BoatsThe sailZO’s frames are placed in slots in the strongback (covered by tape) and supported by molds that extend to the floor.

After the hull is lifted from the building form and turned right-side up, the precut seats and other interior plywood parts are fitted using the same technique applied to the planks. Solid wood parts are not included, and lumber for the breasthook, rubrail, and oarlock pads to finish the hull must be procured by the builder. Plans for the sailing rig are also included in the basic kit, but the builder must supply his own stock and hardware for the mast, boom, and yard, as well as the sail and all hardware and running rigging required.

courtesy of ZO Boats

courtesy of ZO BoatsThe hull is quite stiff after being glued and glassed; once it is off of the jig it will keep its shape without spalls to hold the beam.

The complete kit is includes all of the parts in the basic kit, along with a complete set of spars, sail, and all lines; two pairs of spoon-bladed oars and related fittings; and all hardware necessary to complete the boat, except for solid wood trim parts, epoxy, and fastenings.

John Robson

John RobsonThe light weight of the sailZO makes launching and retrieval easy, even when it can’t be floated off and on the trailer.

Bill and I trailered the sailZO down to the ramp and launched it into Bristol Harbor. The tide was low, and we didn’t have quite enough ramp to float it off the trailer, but this wasn’t a problem because the hull only weighs 150 lbs. A quick push freed the boat from the trailer bunks and left her floating in less than 6″ of water. Her narrow bottom had me slightly concerned when I first clambered aboard and took the forward thwart, but the sailZO proved to be quite stiff.

Bill gave one good push as he boarded, and the boat glided nicely out of the shallows as he settled in to the stern rowing position. We shipped the Shaw & Tenney spoon-blade oars and started pulling for open water. The boat had other ideas, and turned 90 degrees into the mild breeze within a few strokes. Unlike the rowZO version, the sailZO has no skeg aft, and directional stability was, well, anything but. The remedy was a simple one: we dropped the centerboard a few inches and set off again. The boat tracked true and straight, regardless of wind direction. Bill mentioned that the rudder was also very useful in helping the sailing hull track under oar, noting that friction from the steering line gave just enough resistance to hold the blade in proper orientation once set.

John Robson

John RobsonThe sailZO has three rowing stations and can be rowed with one, two, or three people at the oars.

My tandem rowing skills were a bit rusty, but a few off strokes aside, we had a fine time rowing through the anchorage. The boat is both fast and agile; the light weight allows her to respond quickly to each stroke. Rowing on my own was also a rewarding endeavor. The sailZO is a nice size for two, but certainly didn’t feel too big for one, either. In general, she gave us no surprises and performed well under oar power.

We returned to the beach next to the ramp and stepped the rig while the bow was nestled in the sand. The sailZO’s balanced lug rig is a thing of simple beauty, made up of the sail and three short spars—mast, yard, and boom—all of which fit in the boat for trailering. The sail is stored rolled around the boom, and its head left bent to the yard. To rig the boat, the free-standing mast is stepped through the forward thwart. The halyard is made fast to the yard, and then the yard is loosely affixed to the mast with a parrel. The sail rolls off the boom as the halyard is hauled. Once the yard is raised peaked, a second parrel holds the boom to the mast. Finally, the downhaul is tightened, and the two-part sheet is run through a block on the boom. The whole operation is very simple, and, with a little practice, very quick.

John Robson

John RobsonThe author goes along for the ride as ZO Boat’s Bill Koffler, seated amidships, manages the sheet and steers with the tiller lines.

Once rigged, we pushed off yet again. This time I took up station in the sternsheets, while Bill chose the thwart forward of the centerboard trunk. Bill let the sail luff while I worked the lines to lower the centerboard and rudder. The centerboard is unweighted, and requires one line to pull it down, another to raise it.

John Robson

John RobsonThe rudder is controlled by a line threaded through the transom and frames, allowing the boat to be steered from any position in the boat.

The rudder blade is deployed by a single line; pulling the line lowers the blade, while a bungee loop raises it when the line is released. With the rudder line that runs the perimeter of the boat, the sailZO can be steered from either side, or from both sides simultaneously if two hands are used. A push forward on the line will cause the boat to steer toward that side.

John Robson

John RobsonThe spars included with the complete kit are spruce and made by Shaw & Tenney. Leathers on the yard and boom protect the mast’s varnish.

Bill sheeted the sail in and we spirited away on beam reach, slightly erratic because of my unfamiliarity with the steering system. The breeze was mild, perhaps 8 knots or so, but the sailZO responded nicely. It was quick to accelerate, and somewhat quick to heel, though it hardened up well as we pressed along. Its narrow beam makes live ballast essential, and we both scooched to windward a little as she picked up speed.

The sailZO handled well on all points of sail, although Bill, in his forward seating position, did get a little wet while beating into the breeze through the harbor chop. For me, the most difficult part was the steering line, which demanded most of my concentration in order to keep the boat going straight in the direction I wanted to go. Like all things, I’m sure I would get better with practice. I’m also sure that the rudder design could be easily modified to include, or be replaced by, a traditional tiller. Although I did find it tricky, I will also say that it does open up some wonderful possibilities in small boats. Bill and I were able to hand off the steering and sheet to each other without changing position during our sail, and I think once mastered, the rudder line increases the number of tasks that can be performed safely while underway, as well as allowing a solo skipper more trim choices on different points of sail.

All in all, the sailZO is a right smart little boat that can be both built and sailed with an easily attained level of skill and effort.![]()

Christian Smith is a third-generation boatbuilder, and a circumnavigator, chainsaw artist, and general Renaissance man who classifies himself a “new old-school Yankee.” He founded the New Bedford, Massachusetts-based youth boatbuilding program Greenfleet, and he cures his own bacon.

sailZo Particulars

[table]

Length/15′7 ¾″

Beam/4′4 ⅝″

All-up weight with rig, oars and sail/230 lbs

Sail area/61 sq ft

Draft/4″

Draft, board down/ 2′ 3 ⅝″

[/table]

Editor’s Note: 8/21/20 The ZO boat website is no longer active and the company is presumed closed.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Monthly readers would enjoy? Please email us!

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.