Ben Fuller

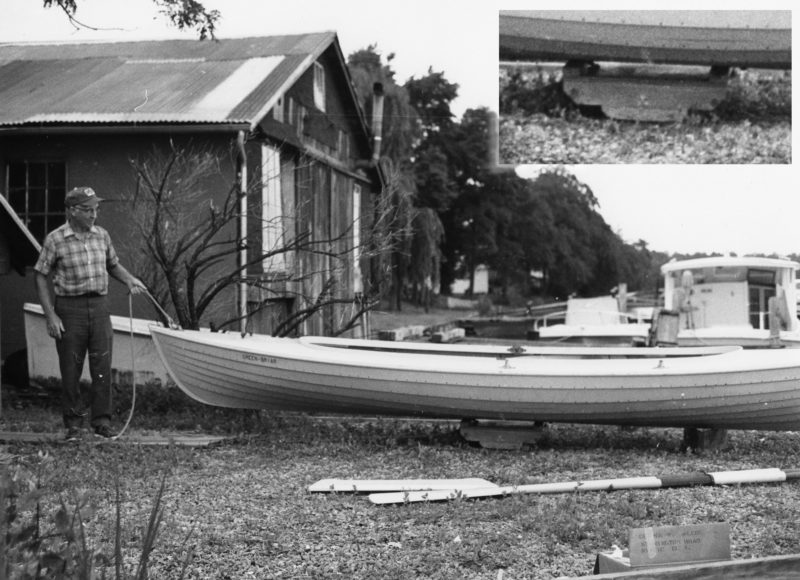

Ben FullerJoe Liener, here with his ducker, GREEN BRIAR, used his roller cart to get his boats to and from the water.

Decades ago, my friend Joe Liener introduced me to duckers and melonseeds at his little boathouse in Wittman, Maryland, on the eastern shore of Chesapeake Bay. Joe had retired some years back from his job as the master of the Philadelphia Naval Yard boatshop where he used what he called a spar cart to move heavy spars and beams. He used a small version of one to get his boats from his boathouse to the water.

The carts are simple, just a roller, an axle, and a frame. Joe’s was pretty light, a 4″ roller, a frame with some plywood for a top, and a couple of boards on it to fit his boats and keep them from rocking. Cheek pieces fastened to the frame had holes to take the roller axle. The cart could also be used, frame down, as a fixed roller, handy for getting a boat out of the water onto a dock or bank or sliding it off or on a trailer.

I thought a cart would be handy for my 13′ 6″ Good Little Skiff, especially since I had no trailer. The bugeye EDNA LOCKWOOD at the Chesapeake Bay Maritime Museum where I worked was getting new masts, so Joe suggested that we take a section of old mast for a roller and bore it for a steel-pipe axle, then make the frame.

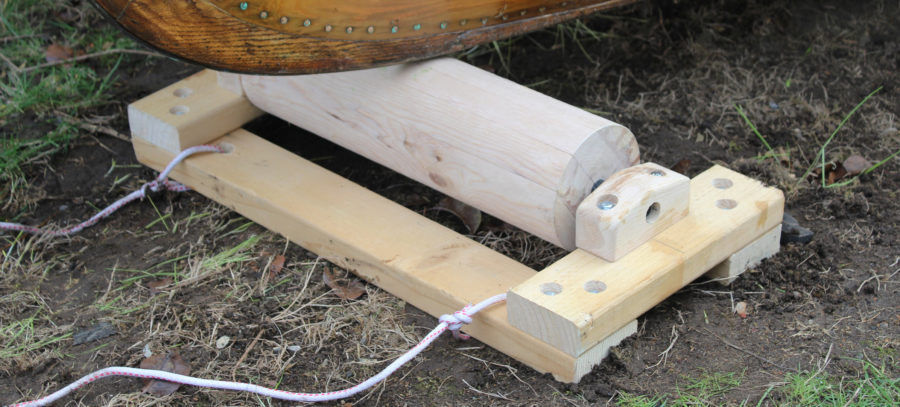

A section from a bugeye’s retired mast serves as the roller.

That 2′ x 8″ roller has now been through several frames, one of which was destroyed in getting several thousand pounds of sandbagger off a marsh. My current frame has cheek pieces incorporated into it and is 26″ wide by 20″ long, all made out of 2x stuff. A piece of steel pipe (1/2″, schedule 80, 0.840 O.D.) works as an axle. Drilling the hole down the center of that old spar was not for the faint of heart. It took Joe’s assistance with a second set of eyes and a big drill for me to bore the hole. There are easier ways to make a roller.

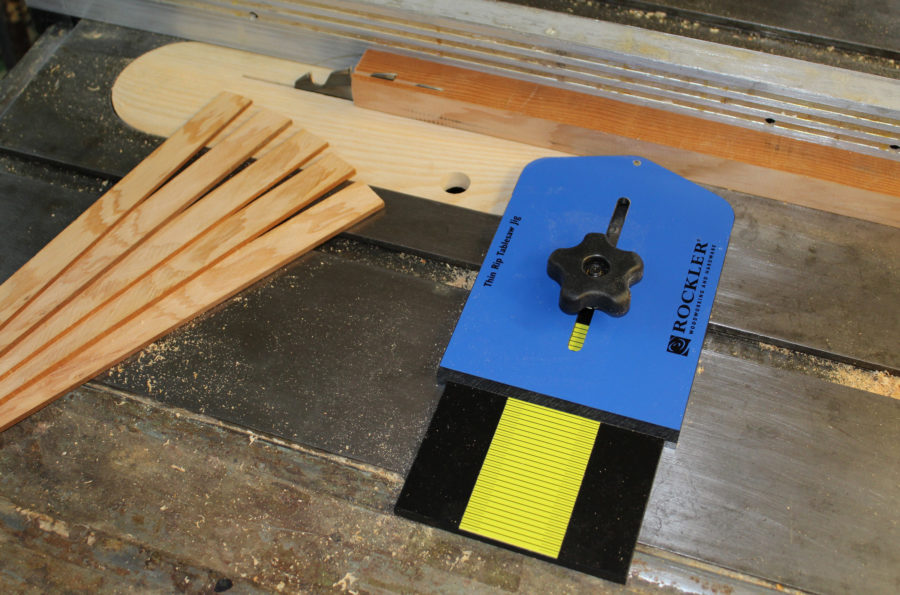

I have made several roller carts using 4″ PVC pipe. Bigger pipe is available and better for going over rough ground. Using a holesaw I cut discs to fit the inside diameter of the pipe and drill a hole to take the axle. I use four discs, evenly spaced along the roller, which is somewhere in the 18″ to 24″ range. I position the hole for the axle so that the roller is about 1/2″ lower than the load, keeping it as low as possible if you need to lift something heavy onto it. Sleeves or bushings of nylon or other slippery stuff would make it easier to roll; I’ve just made a loose hole in the wooden cheek pieces.

I now have more boats than trailers, so I use my roller frequently to swap boats. To take a boat off a trailer, I tie the boat to a solid fixed point and pull the trailer until the boat is at the balance point. I put the roller cart down, roller up, and drop the boat onto the roller so I can slide it into the boathouse, usually using a bunch of 4″ pipe sections for additional rollers. When I use the roller cart to transport a boat, those with fairly flat bottoms like a dory, a skiff, or my ducker sit nicely on the frame. Boats with a very round or V bottom, or a shallow keel, need a hand or chocks on the cart frame to keep them upright.

I’ve used my roller to move heavy stuff like my catboat mast, and I tuck it into the back of the pickup when I am going to do a trailer launch on a shallow beach. It works well moving boats over marsh where I can’t take a trailer. For moving heavy, bulky stuff, Joe’s cart is hard to beat.![]()

For tips on making roller carts, see this month’s From the Editor.

Ben Fuller, curator of the Penobscot Marine Museum in Searsport, Maine, has been messing about in small boats for a very long time. He is owned by a dozen or more boats ranging from an International Canoe to a faering.

You can share your tricks of the trade with other Small Boats Monthly readers by sending us an email.

I tried the 2″ ABS pipe option a long while ago as rollers for my row boat of approximately 150 lbs, but unless the surface was really smooth they didn’t work all that well and were noisy and bouncy on dirt and tend to twist out of alignment so not roll the boat where i wanted it go.I switched to using a 2′ long air-filled 6 inch diameter flexible plastic boat fender about 3 or 4 years ago and it works great and rolls smoothly even on gravel (somewhat like but not likely as rough of surfaces as the big inflatable air bags that were reviewed here in Small Boats Monthly a while back.) The fender will flex around the keel, as well as indent if it encounters smaller rocks and other unevenness along the path and roll over them, usually while remaining square to the direction of travel, etc., but obviously not to the same degree as those big air rollers. It’s also something I can easily take with me in the boat/ vehicle anytime and anywhere I go and usually easily pull the boat well clear of the shore line or launch my boat without having to back my vehicle right to the waterline. This is important if there is any kind of breeze or chop at the launch… it lets you load up the basic safety gear etc you always need…. then go park your vehicle, then come back and complete the rest of the prep—oars into the oar locks ready to row—on dry land. Then I launch, grab the fender, toss it into the bow before it floats away, and then hop in and row away all in one go.

But watch how much of a load you place or have in your hull when using any sort of rollers. I was fully loaded with camping gear and grounded out on a shallow sandy beach about 20 yards from the actual shoreline in my old boat. This was on a camping trip two summers ago. The fender got me to the actual shoreline but the load generated more flex than the epoxy-glued plywood lap joint between my flat bottom board and the garboard strake liked. I heard a minor cracking sound at the time but didn’t think much of it, but sure enough it had sprung a fairly good leak. Thankfully it wasn’t much at all unless I was fully loaded and thankfully even then I could still manage it with just a minute or so of sponge bailing every half hour or so, so the rest of the trip wasn’t a write-off.

Launching or recovering, I place the fender at the end I want to move the boat towards, then lift the other end so both ends are clear and push the boat ahead. Once the other end becomes the heavy end, then i move to that end and lift and pull from there if I need to go farther.

I am looking to find some longer ones so it’s easier to see whether i’ve positioned it exactly square to the direction I’m trying to move the boat. Two might be better if I had to move things longer distances, but one is working fine for me so far at my typical launch sites. I have a proper cart for around home or if I’ve got a long portage.