As I was working on our review of sound signaling devices in our August 2016 issue, I took a look on the web for homemade foghorns. I found quite a number of websites and videos that showed how to make foghorns and train horns out of common plastic pipe and fittings. A trip to the hardware store for some 1/2″ PVC pipe and fittings, and 30 or 40 minutes of puttering in the shop was all it took to come up with a few configurations that made a sound that I liked.

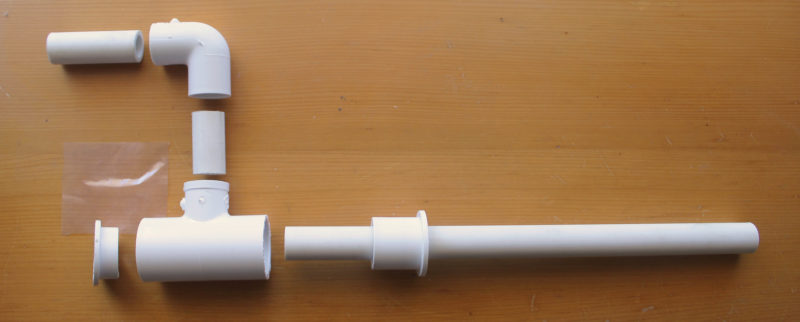

The parts are common plastic pipe and fittings. Only the two reducers need modifying: The one at the back of the horn (left) is shortened and the one at the front reamed out to let the pipe slip through.

The core of the horn is a 1″ x 1″ x 1/2″ T fitting and two 1″ to 1/2″ reducers. One reducer gets shortened up with a hacksaw. (Don’t try using a bandsaw—cylinders like plastic pipe do dangerous things in one.) The cut then gets sanded flat. The other reducer needs to have the stop inside removed so that 1/2″ pipe will slip through. The short reducer is inserted into one end of the T with a piece of freezer bag. The other reducer goes into the other end of the T, and a piece of 1/2″ pipe slips through until it comes in contact with the freezer-bag membrane. You blow through the small hole in the side of the T and adjust the 1/2″ pipe to get a tone. You can change the mouthpiece angle with pipe and angled joints. The length of the pipe slipped through the reducer will determine the horn’s pitch. You can use a long pipe or a short length of pipe—about 6″ so you can still get a grip on it to adjust it—and, if you like, connect a funnel to the pipe. The sound I liked best came from a 24″ length of pipe. It had a deep, resonant, rattling tone.

If I were on the water and heard the deep sound of that 24″ horn coming through the fog, I’d start making tracks fast, thinking I was about to get run down by a freighter. And there’s the problem. You can’t give other mariners the impression that you’re something you’re not. The USCG Colregs specify the frequencies that vessels can use: 70–200 Hz for a vessel 200 meters or more in length, 130–350 Hz for a vessel 75 meters but less than 200 meters in length, and 250–700 Hz for a vessel less than 75 meters in length. (If you’d like to hear what those ranges sound like, check out this online tone generator.)

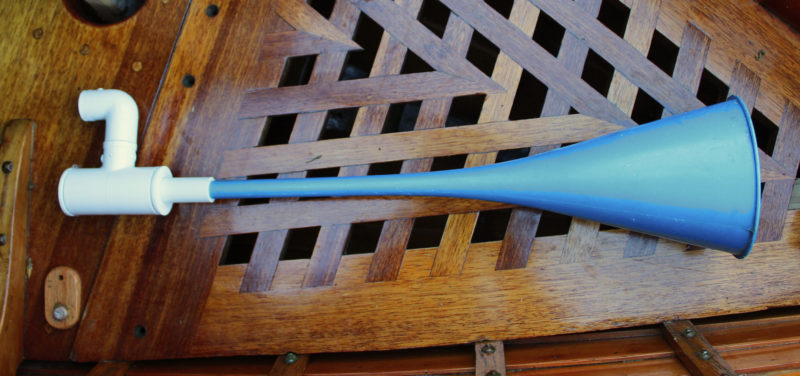

It looks like a horn and has an authoritative voice but this version with the long funnel has a low tone that only a ship can rightfully use.

I sometimes have trouble distinguishing octaves coming from different instruments and couldn’t compare the sound of the tone generator and the horn with any certainty, so I loaded a free tuning app (Pano Tuner for Android) on my phone and found my 24″ pipe was 130 Hz, two octaves below middle C on the piano. If I were to use that horn aboard the biggest of my boats in the fog, I’d be masquerading as a vessel between 250′ and 650′ long. Too bad, I rather like the sound. The lowest tone I can use is 250 HZ, or just a bit below middle C. That’s a 12″ pipe.

While the funnel my have the look of a horn, a straight pipe has a sharper more distinct sound.

This homemade horn may look like it belongs under the galley sink but it is loud and measured up well against all of the lung-powered horns we reviewed. It is practically indestructible and the parts cost less than $5.

I found it easy to get carried away with making horns. I thought a dual horn might be worth investing a couple of dollars more, and indeed a two-tone horn has a sound that’s hard to ignore.

It’s easy to join two horns with a T fitting. This dual horn sounds like a big-rig truck.

![]()

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.